Fashion made in Main Franconia

Ten per cent of global greenhouse gas emissions are generated by the production of clothing and shoes. Around 2,700 litres of water are needed to produce a single T-shirt. The clothing industry is considered to be one of the dirtiest in the world. Legislators are therefore increasingly taking manufacturers to task. For instance, Extended Producer Responsibility (EPR) has been in force in the EU for years. Companies must produce recyclable materials and goods, use recycled fibres, and promote the development of emerging technologies to process and recycle fibres from used textiles. EPR not only applies to manufacturing companies, which are responsible for the entire life cycle of the goods, but also retailers and importers, who place goods on the market.

With the Green Deal, the EU Commission also published a textile strategy in 2022 as part of the action plan for a sustainable circular economy. The aim is to increase the recycling rate in the clothing sector in order to achieve the transition to a climate-neutral, resource-efficient and competitive economy by 2050. Many companies fear that this will lead to a great bureaucratic burden, and not without good reason, because the regulations are complicated and the requirements must also remain practicable. However, smaller labels in particular also see an opportunity in the idea of more sustainability.

One of these labels is WOTE from Würzburg, for example. Its two founders want to offer an alternative to fast fashion brands; the initials of the company name stand for Water, Ocean, Trees, Earth. Britta Doppelfeld and Matthias Jobst want to combine sustainable and fair clothing produced in Europe with quality and timeless design. And “second life” is also playing an increasingly important role for them in their commitment to sustainable consumption. Second-hand textiles are redesigned together with a local seamstress into a new style and then resold as unique items. The textiles are currently sold exclusively online.

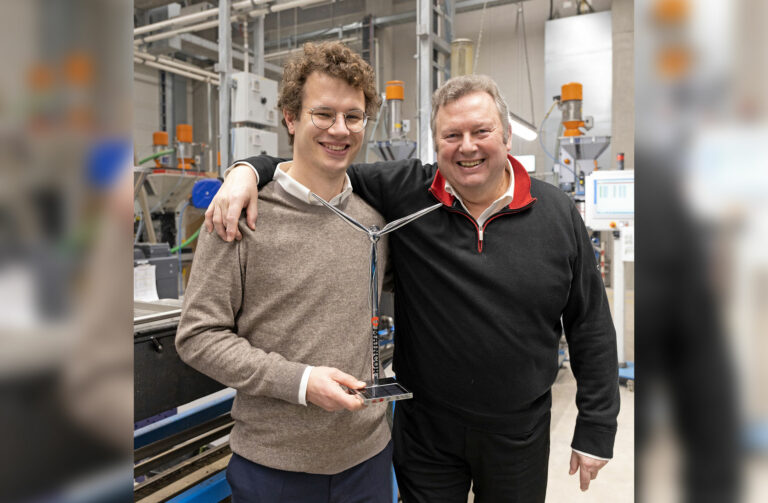

Back in 2012, the basic principle of sustainability motivated the then 23-year-old Lukas Weimann from Schweinfurt to found his label. Today, P.A.C. is a family-run specialist company for textile accessories – headwear, neckwear and knitwear as well as functional socks – with production facilities in Germany and Italy and a significant customer base all over the world. The Schweinfurt-based business even exports its multifunctional scarves, which are cooling or warming, wick away moisture or protect against UV radiation, to Asia. In-house electricity production, the recycling of PET and marine plastic and use of water-based or even vegetable-based dyes are as much a part of the company’s DNA as social inclusion in production. The approximately 80 employees were able to celebrate their tenth anniversary in the new “P.A.C. Green Factory”. The CO2-optimised textile factory is comprehensively digitised and offers 6,000 square metres of space for production and logistics, as well as another 1,200 square metres of office space for up to 200 people. In 2023, P.A.C. was awarded the Bavarian SME Prize for outstanding entrepreneurial achievements as a supporting pillar of the Bavarian economy and society and honoured as one of “Bavaria’s Best 50” of 2023.

S.Oliver owner Bernd Freier started out similarly small in 1969 – with a 25 square metre boutique called “Sir Oliver” in Würzburg’s city centre. Coming from a humble background, the founder chose Oliver Twist as the namesake for his business – a boy who sets out to seek his fortune with great courage. And this has undoubtedly succeeded. Today, the Group of companies is one of the largest European fashion and lifestyle companies with a brand turnover of 915 million euros in 2021 and has a presence on all continents. For many years now, the s.Oliver logo has not only adorned items of clothing, but licences have also been granted for perfumes, accessories, eyewear, jewellery, watches and home textiles. The success of the fashion company, which employs more than 5,100 people around the world, about 1,600 of them in the region, is managed from the small town of Rottendorf near Würzburg.

The company is growing steadily, also thanks to the establishment and positioning of new brands such as Comma, Liebeskind Berlin or Copenhagen Studios. In order to be able to cover the highly developed logistics processes, the Group is currently investing an amount in the high double-digit millions in a new logistics centre in Dettelbach, which will cover almost all of the brands’ logistics processes starting from 2024 with a floor space of 78,000 square metres and is designed for around 60 million outgoing goods per year.

Drykorn has an equally impressive track record. The label’s management, administration, design, product management and logistics are located at its head office in Kitzingen. Founded by Marco Götz in 1996 out of a liking for women’s and men’s trousers, the company developed into a full-service provider and international fashion label within a few seasons. It enjoys cult status among its fans and stands for a sustainable idea – for example, the company plants a tree seedling in the mangrove forests of Madagascar for every order that is not returned in full – as well as exceptional quality in an upmarket price range. Over two thirds of all the garments are produced in Europe. “Metropolitan, accessible and progressive” are the characteristics that define the label and appeal to style-conscious individualists – with its own stores in major European cities too. The Kitzingen-based company wants to become more global and increase its export share in the next few years.

Minx Fashion GmbH, founded in 1982, set out to enter the European market in 2017 after being taken over and restructured by Philipp von Ilberg, Marcus Kossendey and Alexander Heyduck. In addition to the DACH region (Germany, Austria, Switzerland), which represents the core market, the Schwarzach-based company is also focusing on other European countries. Its label Minx is a premium ready-to-wear collection for style-conscious women.

The second label Sallie Sahne caters to sizes 42 to 54 while providing the same quality. The sense of timeless elegance, quality and an awareness for the craft of tailoring are what sets their work apart. Anja Diskin, who previously worked for well-known labels in haute couture, is responsible for the design, which is developed in the in-house design studio for “Made in Europe” production – primarily in Italy and Eastern Europe. Two main collections and two intermediate collections, each with around 80 to 20 styles, are developed by the currently 20 employees each year.

Authentic Style, based in Marktbreit, has been designing, producing and selling fashion for young people since 1991. The second generation of the family has already taken over the management of the company. With its own brands such as Eight2Nine and SkyRebel, the company has developed into a leading fashion provider in the young fashion segment. It is active in both B2C and B2B sectors and covers the entire value chain, from production to shipping.

Czerny Manufaktur GmbH from Gemünden, a company with a history of more than 80 years in the fashion industry, should not be missing from the line-up of Main Franconian fashion designers with a long tradition. With the sisters Magdalena Cromme and Eva-Maria Czerny, the business, founded in 1941, is already under the management of the third generation of the family. The company became known nationwide mainly for folk fashion and the “Basset” label created in 1984, which is now history. It was completely replaced in 2021 by the “Von&Zu” brand, which was launched in 2014 and developed in parallel. This was the fashion company’s response to their customers’ changing demands. Today’s target customer is not necessarily younger, but at least 35 years old and younger at heart. The new label is therefore more progressive and promises uncomplicated, functional fashion that still looks good. But above all, the Gemünden fashion designers consistently focus on limitation with the new brand for reasons of sustainability. The production is done exclusively in the EU and produces according to demand, meaning they only produce what retailers actually ordered. Currently, the company employs around 25 people at the small factory in Gemünden, where the collections are designed and samples are produced.

Finally, Ulla Miederfabrik is a niche provider and therefore very successful. What began in 1949 with the company founders Gerhard and Eleonore Weidauer and two sewing machines in Leinach near Würzburg has been continued through the years and is now in the third generation under the leadership of Toni and Stella Weidauer since 2015. The family business supplies specialist retailers throughout Germany and Europe with lingerie, nightwear and swimwear. From the very beginning, Ulla has seen itself as a specialist for large sizes and has a range of different brands in addition to the Ulla Lingerie Féminine collection. The majority of the products are manufactured on site and also at two smaller factories in Latvia and Slovenia.

Luckily, the fashion sector is also still interesting for start-ups. The fashion start-up Deetory in Winterhausen is a good example of this. Sebastian Becker and Julian Reischmann want to combine cool looks with a clear conscience and have focused on fairly produced and traded clothes. The customer decides which charity the company should donate part of its profits to. They have even introduced their own currency for this, called “Dees”. Customers receive these with their purchase in the online shop and can then divide them up as they wish.

However, Main Franconia is not only “fashion smart” in the creative and production sectors. The region is also home to traditional fashion retailers. From locally established, family businesses such as Schlier in Würzburg, which turned 180 in 2023, the owner-managed Würzburg gentleman’s outfitter Severin and the fashion house Iff in Gerolzhofen to numerous young, trendy boutiques throughout Main Franconia and internationally active chain stores such as Frankonia from Rottendorf.

Since 1907, the latter have been selling upmarket fashion from well-known brands from the classic Anglophile and timeless sporting sector to functional outdoors clothing and have acquired a name for themselves especially as a hunting equipment supplier due to their expertise in the field of hunting weapons with their own gunsmith’s workshop.

Header picture: Lifestyle hat and neckwear from Main Franconia