Top-tier motorsport – made in Main Franconia

Formula 1 is the premier league of motorsport. This sport uses cutting-edge technology, which will find its way into series production many years later. Some of these technologies are developed, built and tested in Main Franconia.

Kimi Raikkonen, one of the most popular Formula 1 drivers of all time, probably owes his first and only World Championship to a small gearbox failure. At the 2007 Brazilian Grand Prix, he was seven points behind leader Lewis Hamilton and in third place in the rankings. But chance – and technology – decreed that Hamilton’s gearbox briefly went on strike on lap eight. The Brit lost more than 30 seconds – and in the end the World Championship. This tragic case clearly shows: Formula 1 teams are highly dependent on technology, which is often a deciding factor between victory and defeat. Some parts are produced by manufacturers such as Ferrari, Mercedes or Red Bull themselves, but the majority comes from suppliers all over the world. Two of these companies are based in Schweinfurt.

Svenksa Kullagerfabriken (SKF)

The Swedish global group SKF has had its German head office in Schweinfurt since the early 1930s. In addition to main development centres and a large part of the production, it is also home to what the company claims is the world’s most efficient large bearing test centre. SKF’s focus is on the production of rolling bearings, bearing units and seals, among other things for conventional passenger cars.

However, a small group of engineers and technicians – the Racing & Special Bearings Unit – deals exclusively with the development of components for automotive racing. There are around 150 SKF parts in a Scuderia Ferrari Formula 1 car, for example the ball and roller bearings for wheel hubs or clutches. Most of these parts are built by Steffen May and his team. The engineers led by May are taking radical approaches to meet the highest performance standards. “Every normal car driver wants bearings that will last the vehicle’s whole life,” explains the engineer. By contrast, Formula 1 customers have completely different priorities: “Of course, the reliability of the bearings is absolutely essential in Formula 1 as well. But here the bearings don’t necessarily have to last more than five races.” It is much more important that the bearings withstand extreme loads. In Formula 1, such loads include exceptionally high speeds and operating temperatures. At the same time, the bearings must be small and light – the lower the weight, the faster the racing car.

To achieve this goal, the engineers reach deep into the materials science bag of tricks. Special steel alloys are just as much a part of everyday life in the Racing & Special Bearings Unit as patented aluminium materials or ceramic balls. “We use very hard sintered metals for gearbox and wheel bearings. For turbo applications, on the other hand, we use metals with a high nitrogen content, for example our very own Nitromax aluminium,” says Jeroen Wensing, Head of Racing Innovations at SKF. To keep up with the rapid pace of development in Formula 1, SKF has introduced special product development and production processes. “Compared to the automotive industry, the pace of development in racing is incredibly rapid. Usually, several product updates are required in a single season,” says Wensing. The consequence: SKF development engineers usually meet with “their” Formula 1 team every week. This requires maximum flexibility. Formula 1 simply has its own rules.

ZF Race Engineering

It takes less than five minutes to find your way on foot to the second big Formula 1 supplier from Schweinfurt. ZF Race Engineering GmbH – a wholly owned subsidiary of ZF Friedrichshafen AG – is situated across the street. The approximately 90 employees develop, produce and distribute shock absorbers, clutches, gearboxes and other products for a wide range of applications in motorsport worldwide. The Formula 1 teams equipped by ZF have so far achieved more than 130 victories and nine world championship titles – according to ZF.

In the 2023 season, four teams – Ferrari and Red Bull, Haas and Alpha Tauri – are relying on the expertise from Schweinfurt. While Scuderia Ferrari install ZF shock absorbers in their cars, Red Bull Racing uses clutches from the Schweinfurt-based manufacturer. The engineers and technicians in the company are well aware that the clutch can make the difference between victory and defeat right from the start. “We therefore try to always provide the highest performance and reliability,” explains Moritz Nöding, press officer of ZF Race Engineering GmbH. “The Formula 1 clutches are designed for maximum performance with minimum space requirements.” Weighing less than 1,800 grams, an F1 clutch weighs just ten per cent of a standard commercial clutch for passenger cars. At the same time, however, the clutch transmits more than 1,200 Newton metres of torque. For comparison: a “normal” passenger car clutch only manages about 250 Newton metres. Of course, this requires special materials: the clutch housing is made of titanium, the friction linings themselves are made of carbon, probably the most important material in Formula 1, which is also used for the chassis and monocoque.

Reliable technology from Schweinfurt

Whether it’s SKF or ZF Race Engineering, neither company is not aware of any case where one of their products led to the technical failure of a Formula 1 racing car. But both companies know that they are working at the limits of what is technically possible – everyday life in top-tier motorsport, made in Main Franconia. And Lewis Hamilton? The Brit has probably overcome the humiliation of 2007 by now. Together with Michael Schumacher, he is a record seven-time world champion today.

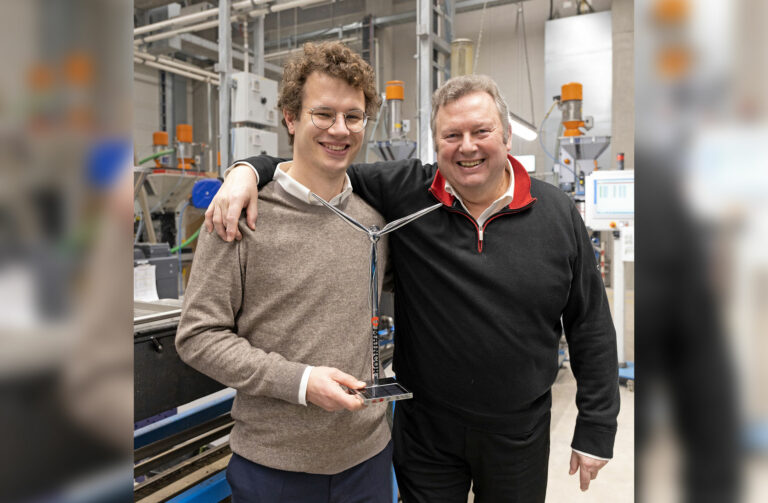

Header picture: ZF clutches: Nine world championships have been won by Formula 1 teams operating with ZF clutches. Photo: SKF